Peat

Two important chapters of Estonian industrial history are intertwined in the story of the Ellamaa power station, i.e. the peat industry and the production and distribution of electricity. From the beginning, the idea was that the power station would be heated by peat, and was therefore built as close as possible to the peat bogs. As of 1922, the State Peat Industry started to organise peat production in several Estonian bogs, including the Ellamaa and Sooniste bogs from which the Ellamaa power station got its heating peat.

In the Estonian climate, peat cutting is a seasonal job and hundreds of summer workers had to be found for the peat industry in Ellamaa. From 1920s to 1930s, the Ellamaa peat industry mainly used labour from Petseri. During World War II and thereafter, war prisoners were also used. The working conditions in the peat bog were extremely harsh. The mechanisation of peat production had already started in the 1860s, including in the Sindi peat factory and several manors in Estonia but, until the 1950s, most of the work was still done by hand.

The elevator press was the most important of the early machines used in the peat industry. The workers would toss pieces of peat cut from the peat mine onto its transportation belt, which passed by the crusher at the other end. The resulting peat mass was compressed into loaves with the help of a press, which were thereafter taken to peat stacks to dry. Initially this was done by hand, but later rope conveyors were used. At first, the elevator presses were powered by portable engines, i.e. steam engines on wheels, and later by electric motors. From 1922, the Ellamaa peat industry used elevator presses built at the Franz Krull machine factory and at the Riigi Sadamatehased (National Industries of the Port of Tallinn).

Since the operation of the Ellamaa power plant was based on peat heating, the necessary rooms for peat drying, storage and transport had to be built and the necessary equipment installed. A huge peat storage, and several other auxiliary buildings were adjacent to the main building of the power plant. In addition, separate spaces were built for the peat moss factory. Thus, it can be said that, for at least one period of its history, the power station was also a peat factory and, in the 1930s, the peat moss it produced was even exported to the United States.

Illustrations:

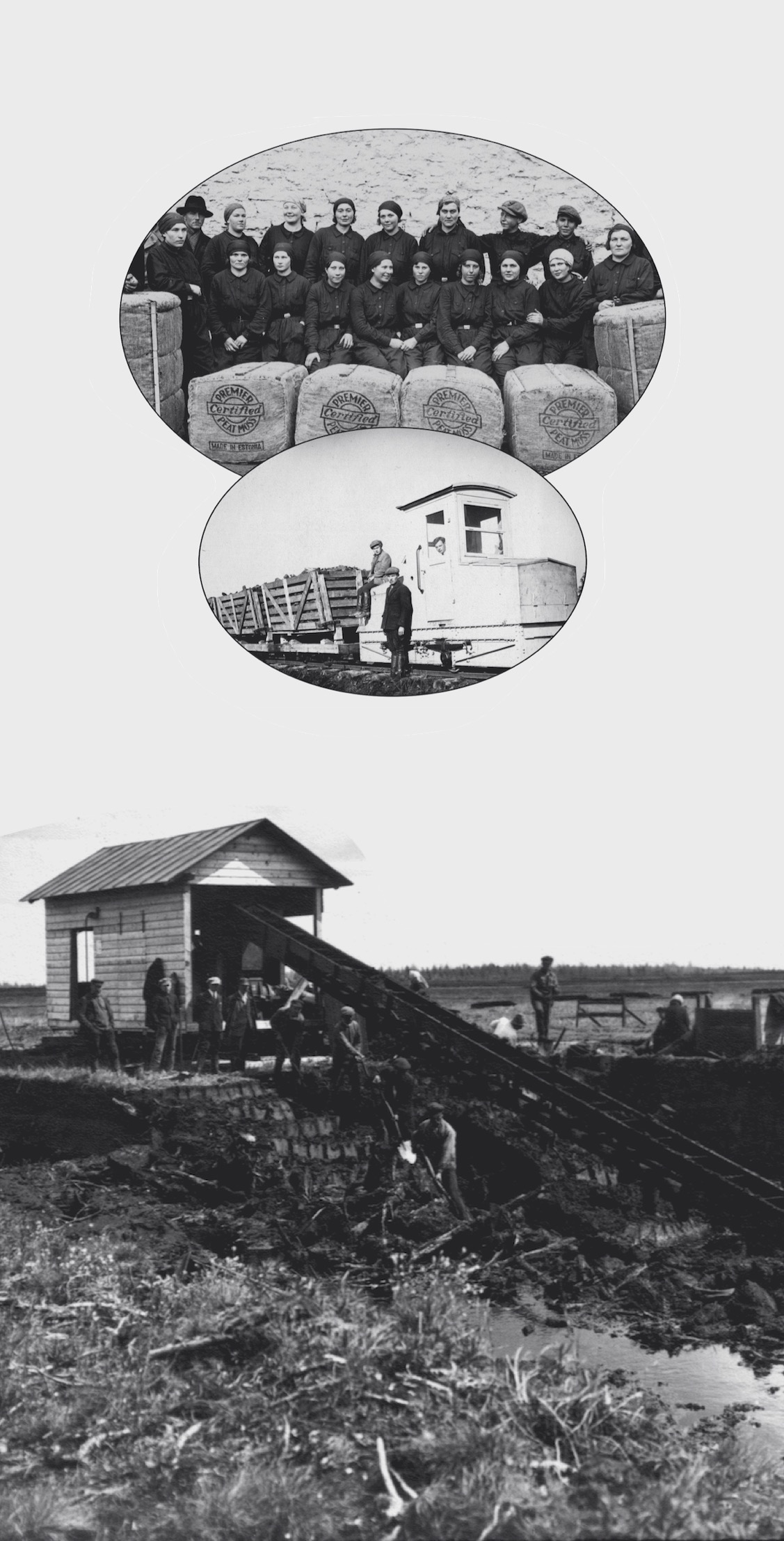

In the 1930s, the production from the peat moss factory operating at the Ellamaa power station was even exported to the United States. In the photo, workers with peat moss bales. Turba Library

The peat loaves were transported from the peat stacks with wagonettes to the power station. The small locomotive in the picture was manufactured in the Franz Krull factory. MOMU Motorsports Museum

In the 1920s, elevator presses were introduced more widely in Estonian peat industries, which made peat processing faster and more efficient. MOMU Motorsports Museum